Welding Strength for the Energy Sector

Friction Welding for Oil & Gas Applications

How MTIW is Making a Difference in Oil & Gas Manufacturing

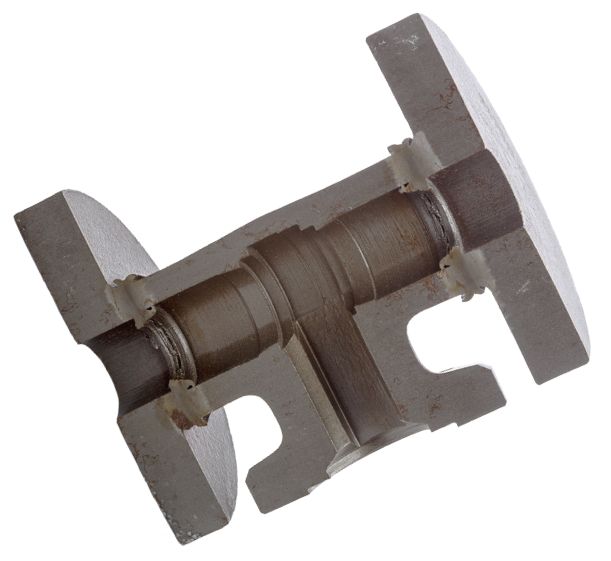

Harbison-Fischer, which specialises in subsurface oil field rod pumping processes, had an issue with an integral pump part that was taking too long to create and costing too much to produce. MTI created a cost-cutting, time-reducing friction welding machine that met the client’s expectations. In response to client requirements, MTI was able to cut the client’s Monel consumption in half for this product process and in addition, Harbison-Fischer benefited from lower expenses and faster output because they were able to eliminate processes. MTI also created two new innovative tactics (quick change tooling and the shear die design on the machine) that may be used for other applications.

Why Friction Welding is Vital for Oil & Gas Applications

Since a typical string of drill pipe can be three to four miles long, composed of 30-foot sections, weld integrity is a must in the oil field drilling industry. Friction welding supports the lower drill stem assembly (made up of other drill pipes, drill collars, and the drilling bit) and transmits the rotary torque needed for drilling. Friction welding produces a metallurgical bond strong enough to take the high torque and highly loaded rotary tension due to directional drilling.

Video courtesy of Zipp Industries GmbH & Co. KG. Video shows a newly installed MTI drill pipe machine in production.

Advantages & Benefits

Powering Efficiency and Safety in Oil and Gas Operations

MTI’s friction welding technologies are revolutionising the oil and gas industry with unparalleled precision and durability. Our innovative solutions offer a perfect blend of efficiency, quality, and sustainability, enabling companies to enhance their operations while meeting the industry’s demanding safety and environmental standards.

Reduced Preparation

The reduced preparation of friction welding is crucial for the oil and gas industry as it significantly cuts down on production time and costs. Friction welding requires minimal surface cleaning and alignment for parts, making it ideal for quick, efficient repairs and assembly of pipelines and drilling equipment. Components do not have to be thoroughly cleaned before friction welding as the process actually acts as a surface cleaner for joining components.

Forged Quality

Friction welding is highly beneficial to the oil and gas industry because it produces exceptionally strong, defect-free joints that can withstand extreme pressures and temperatures. This is critical for the integrity and safety of pipelines and equipment in harsh environments. The process also reduces the need for additional materials or filler metals, which can enhance corrosion resistance and durability. As a result, it minimises maintenance costs and extends the lifespan of critical infrastructure.

Machine-Controlled Process

Friction welding provides the oil and gas industry with precise, consistent, and repeatable welds, crucial for maintaining the high safety and performance standards required. The process automation minimises human error and ensures uniform quality across large-scale production, which is essential for critical infrastructure like pipelines. It also increases production efficiency and reduces labor costs by streamlining the welding process.

Green Technology

Friction welding is beneficial for the oil and gas industry as it aligns with the growing emphasis on sustainable practices and reducing environmental impact. Friction welding generates less waste and emissions compared to traditional welding methods, which helps in minimising your carbon footprint. Additionally, its lower energy consumption contributes to overall cost savings and promotes more sustainable operation. Friction welding’s environmental advantages support regulatory compliance and improve the industry’s reputation regarding environmental responsibility.

The reduced preparation of friction welding is crucial for the oil and gas industry as it significantly cuts down on production time and costs. Friction welding requires minimal surface cleaning and alignment for parts, making it ideal for quick, efficient repairs and assembly of pipelines and drilling equipment. Components do not have to be thoroughly cleaned before friction welding as the process actually acts as a surface cleaner for joining components.

Friction welding is highly beneficial to the oil and gas industry because it produces exceptionally strong, defect-free joints that can withstand extreme pressures and temperatures. This is critical for the integrity and safety of pipelines and equipment in harsh environments. The process also reduces the need for additional materials or filler metals, which can enhance corrosion resistance and durability. As a result, it minimises maintenance costs and extends the lifespan of critical infrastructure.

Friction welding provides the oil and gas industry with precise, consistent, and repeatable welds, crucial for maintaining the high safety and performance standards required. The process automation minimises human error and ensures uniform quality across large-scale production, which is essential for critical infrastructure like pipelines. It also increases production efficiency and reduces labor costs by streamlining the welding process.

Friction welding is beneficial for the oil and gas industry as it aligns with the growing emphasis on sustainable practices and reducing environmental impact. Friction welding generates less waste and emissions compared to traditional welding methods, which helps in minimising your carbon footprint. Additionally, its lower energy consumption contributes to overall cost savings and promotes more sustainable operation. Friction welding’s environmental advantages support regulatory compliance and improve the industry's reputation regarding environmental responsibility.

Our Commitment

Innovating with Integrity, Delivering with Quality

MTI brings the highest possible degree of safety and quality, whether it’s a part we’re welding or a machine we’re building. We are equipped to produce parts for the most sensitive environments and exacting standards.

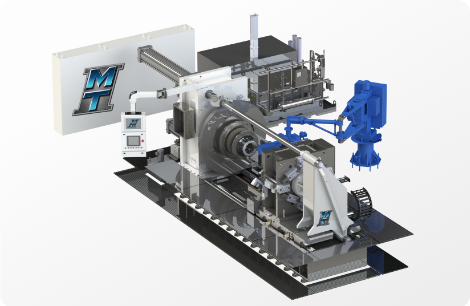

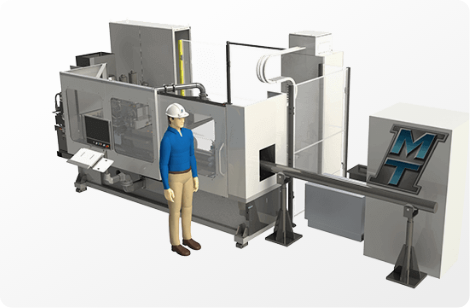

Friction Welding Machines for the Oil and Gas Industry

Machine-welded components are 100% solid-state bonded and are produced quickly and consistently, free of operator-made errors. This makes friction welding ideal for drill pipes, valves, and other drill stem components meant to withstand the high torque and rotary tension of directional drilling.

MTI offers the design and manufacture of friction welding machines, both semi and fully-automated, to meet the challenges of the oil and gas industry.

Friction Welding Machines for the Oil and Gas Industry

Machine-welded components are 100% solid-state bonded and are produced quickly and consistently, free of operator-made errors. This makes friction welding ideal for drill pipes, valves, and other drill stem components meant to withstand the high torque and rotary tension of directional drilling.

MTI offers the design and manufacture of friction welding machines, both semi and fully-automated, to meet the challenges of the oil and gas industry.

ROTARY FRICTION WELDING

MTI’s Rotary friction welding requires no prior joint preparation, saving time by not having to store pipes and other materials from the elements.

LOW FORCE FRICTION WELDING

Low Force friction welding can streamline production with a smoother flash on a wide range of parts.

Explore Our Sample Parts

What you are wondering now has been done before. Explore our samples to find the ideal applications, materials, and geometric fittings for your next project in the oil and gas industry.

Contract Manufacturing Services

Our friction welding process equips you from start to finish. Whether you need friction welding machines or are looking to develop parts, we provide the in-house machines, lab, and knowledge necessary, including on-site service for operators and production assurance.

Contract Manufacturing Services

Our friction welding process equips you from start to finish. Whether you need friction welding machines or are looking to develop parts, we provide the in-house machines, lab, and knowledge necessary, including on-site service for operators and production assurance.

Learning Center

Featured Articles

Case Studies

Videos

Oil & Gas Video

Oil & Gas Video

Get the information you need, before you need it — free and straight to your inbox from industry experts.